|

| HOME ABOUT US STEWARDSHIP PRODUCTS PHOTO GALLERY CAREERS SITEMAP CONTACT REQUEST | |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Performance characteristics

|

Thickness, mm

|

Values

|

| Adhesion strength of coating | 9 - 24 | The coating peels off together with the outer veneer and the cut has sharp edges. A layer of wood fibers can be clearly seen on the underside of the cut edges |

| Steam resistance of film coating | 9 - 24 | No swelling. Slight loss of gloss. No bubbles. |

| Resistance of film coating to sodium hydroxide (NaOH) | 9 - 24 | The color of the solution is from colorless to light yellow. Slight gloss variation, the film coating is firm and resistant to mechanical stress, a mark from the bottle neck can be seen |

| Resistance of film coating against concrete | 9 - 24 | No staining of the concrete. No gloss variation, film coating is firm |

| Surface waviness of the film-faced birch plywood (Rippling test) |

9 - 24 | Average rippling length is not more than 20 mm |

| Film coating resistance to abrasion (Taber-test), revolutions, not less | 9 - 24 | 300 |

| Film coating resistance to cracking | 9 - 24 | Crack index not exceeding 80 |

| Water permeability of film coating (Cobb test), g/m2, not more than: |

9 - 24 | 400 |

Note 1 : The above properties are declared by the producer Mills in Russia and is believed to be correct and fair view of the products. |

||

What does our promise of Efficiency mean to you

- Products that improve your cost, material and energy efficiency

- Reliable and timely deliveries

- Local knowledge, support and service

- Solutions for every formwork application

- Proven and documented technical data and environmental statements

Effect of humidity and moisture

- Wood veneer is a living material and is subject to moisture movement according to surrounding conditions, which affects the flatness of panels. It is important to condition the panels to reach a moisture content near to the equilibrium of their permanent environment.

- Like other wood-based panel products, Birch Plywood is also hygroscopic and its dimensions change in response to a change in humidity. A change of 1% in moisture content typically increases or decreases the length, width and thickness by 1% in dimensions and thickness. It is therefore desired that the edges are sealed with a suitable acrylic paint to prevent and/or control ingress of moisture and humidity and consequent swell in thickness and expansion in dimensions.

- The recommended stocking conditions are 20°C and a RH of air of about 60%.

Storage conditions:

When first exposed to the prevailing weather conditions at Site and during the early uses of the boards, there is likely to be some localised swelling of the wood veneer caused by moisture pickup, which may leave impressions in the face of the concrete. To prevent this:

- Store the panels in dry conditions, flat on a level surface, off the ground and direct sunlight, preferably indoors or under the shed.

- Panels should be store horizontally on a firm base with enough bearers to prevent sagging.

- The stacks should be covered k to protect top and edges from moisture penetration as fluctuations in temperature and humidity may cause panels to distort.

Safe Handling

Film faced plywood sheets are very slippery; sliding panels may lead a whole stack to collapse. Remember, separate sheets must be moved manually by two persons. Panels must not be pulled or pushed on the floor or ground. Handling plywood requires general safety procedures and proper equipment. Handling should be kept to a minimum, and for speed and efficiency, mechanical handling devices should be used whenever possible. When taking a panel from a pack or a stack, it must be lifted, not pulled over the surface of the bottom panel, because any hard particle (sand or film particle) between panels can lead to damage of processed or coated surfaces.

Preservatives

![]() Plywood is made from natural Birch wood Veneers grown and harvested in Russia and is free from any toxic chemicals except resin. As is common knowledge, all wood products are susceptible to insects or termites and/or borers present in different climatic zones in the soil or buildings. It is recommended that the users are applying the coat of suitable chemicals or insecticides on all exposed surfaces of wood in addition to treatment of masonry foundations of the building where the Wood products are required to be use. Fipronil emulsified concentrate at about 3% is one such chemical and effective deterrent against insects and pests or termites in tropical climate zones. However, the application should be in accordance with manufacturers guidelines for effective results. Users own discretion in selection of appropriate chemical and its doses or frequency of such treatment is advised for satisfactory results in the light of experience gained over the period of time.

Plywood is made from natural Birch wood Veneers grown and harvested in Russia and is free from any toxic chemicals except resin. As is common knowledge, all wood products are susceptible to insects or termites and/or borers present in different climatic zones in the soil or buildings. It is recommended that the users are applying the coat of suitable chemicals or insecticides on all exposed surfaces of wood in addition to treatment of masonry foundations of the building where the Wood products are required to be use. Fipronil emulsified concentrate at about 3% is one such chemical and effective deterrent against insects and pests or termites in tropical climate zones. However, the application should be in accordance with manufacturers guidelines for effective results. Users own discretion in selection of appropriate chemical and its doses or frequency of such treatment is advised for satisfactory results in the light of experience gained over the period of time.

Reuses

Typical number of reuses is likely to be in the range of 20-30 times. However, this will vary according to many different factors including good site practice, the required concrete finish, the amount of care taken when compacting the concrete, handling and storage of panels, type and quality of release agent used on the panels before concreting.

The number of times the plywood can be reused is only intended as an approximate guide. It does not imply any form of warranty. The actual number of reuses will depend on several factors other than the plywood.

Design Data

LOAD RESISTANCE q [kN/m2] AND CORRESONDING DEFLECTION u [mm] VALUE FOR BIRCH FILM FACE PLYWOOD TO BE USED IN THE DESIGN OF CONCRETE FORMWORKS***

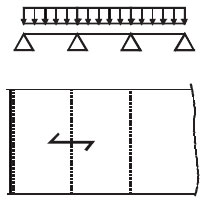

Load resistance for a uniformly distributed load on a continuous plate strip with three equal span lengths. Face grain parallel to span

| Span | Nominal thickness (mm) |

||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| c/c | 9 | 12 | 15 | 18 | 21 | 24 | |||||||||||||||||

| mm | q | u | q | u |

q |

u | q |

u | q |

u |

q |

u |

|||||||||||

| 100 | 123 | s |

0.3 | 166 | s | 0.3 | 193 |

s |

0.2 | 234 |

s |

0.2 |

263 |

s | 0.2 | 303 | s | 0.2 | |||||

| 150 | 82 | s |

0.8 | 111 | s | 0.6 | 129 |

s |

0.4 | 156 |

s |

0.4 | 176 |

s | 0.3 | 202 | s | 0.3 | |||||

| 200 | 61 | s |

1.6 | 83 | s | 1.1 | 97 |

s |

0.8 | 117 |

s |

0.7 | 132 |

s | 0.6 | 152 | s | 0.5 | |||||

| 250 | 46 | b |

2.7 | 67 | s | 2.0 | 77 |

s |

1.4 |

94 |

s |

1.1 | 105 |

s | 0.9 | 121 | s | 0.8 | |||||

| 300 | 32 | b |

3.7 | 51 | b | 3.0 | 64 |

s |

2.2 | 78 |

s |

1.8 | 88 |

s | 1.4 | 101 | s | 1.2 | |||||

| 350 | 24 | b |

5.0 | 38 | b | 4.0 | 55 |

b |

3.4 | 67 |

s |

2.6 | 75 |

s | 2.1 | 87 | s | 1.7 | |||||

| 400 | 18 | b |

6.4 | 29 | b | 5.0 | 42 |

b |

4.2 | 58 |

b |

3.7 | 66 |

s | 2.9 | 76 | s | 2.4 | |||||

| 500 | 12 | b |

9.8 | 18 | b | 7.6 | 27 |

b |

6.4 | 37 |

b |

5.5 | 49 |

b | 4.9 | 61 | s | 4.3 | |||||

| 600 | 8 | b |

13.9 | 13 | b | 10.8 | 19 |

b |

8.9 | 26 |

b |

7.7 | 34 |

b | 6.8 | 43 | b | 6.1 | |||||

b = bending strength limitation

s = planar shear strength limitation

|

Short-term loading Service Class 3 kmod = 0.70 kdef = 0.40 γq= 1.2 γm = 1.3 q given in kN/m2 u given in mm |

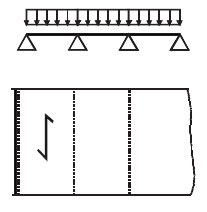

Load resistance for a uniformly distributed load on a continuous plate strip with three equal span

lengths. Face grain perpendicular to span

| Span | Nominal thickness

(mm) |

||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| c/c | 9 | 12 | 15 | 18 | 21 | 24 | |||||||||||||||||

| mm | q | u | q | u | q | u | q | u | q | u | q | u | |||||||||||

| 100 | 108 | s | 0.4 | 133 | s | 0.3 | 176 | s | 0.2 | 205 | s | 0.2 | 245 | s | 0.2 | 276 | s | 0.2 | |||||

| 150 | 72 | s | 1.1 | 89 | s | 0.7 | 118 | s | 0.5 | 137 | s | 0.4 | 163 | s | 0.4 | 184 | s | 0.3 | |||||

| 200 | 51 | b | 2.3 | 66 | s | 1.3 | 88 | s | 1.0 | 103 | s | 0.8 | 123 | s | 0.6 | 138 | s | 0.5 | |||||

| 250 | 33 | b | 3.4 | 53 | s | 2.4 | 71 | s | 2.4 | 98 | s | 1.3 | 98 | s | 1.0 | 111 | s | 0.9 | |||||

| 300 | 23 | b | 4.8 | 40 | b | 3.6 | 59 | s | 2.8 | 68 | s | 2.0 | 82 | s | 1.6 | 92 | s | 1.3 | |||||

| 350 | 17 | b | 6.4 | 29 | b | 4.7 | 45 | b | 3.8 | 59 | s | 3.0 | 70 | s | 2.4 | 79 | s | 1.9 | |||||

| 400 | 13 | b | 8.2 | 22 | b | 6.1 | 35 | b | 4.9 | 49 | b | 4.2 | 61 | s | 3.4 | 69 | s | 2.7 | |||||

| 500 | 8 | b | 12.7 | 14 | b | 9.2 | 22 | b | 9.2 | 32 | b | 6.2 | 43 | b | 5.4 | 55 | s | 4.8 | |||||

| 600 | 6 | b | 18.2 | 10 | b | 13.1 | 15 | b | 13.1 | 22 | b | 8.7 | 30 | b | 7.5 | 38 | b | 6.7 | |||||

b = bending strength limitation

s = planar shear strength limitation

|

Short-term loading Service Class 3 kmod = 0.70 kdef = 0.40 γq= 1.2 γm = 1.3 q given in kN/m2 u given in mm |

*** Obtained from Handbook of Finnish Plywood covering Birch Plywood FFP (Page 54)

Disclaimer:

Eximcorp India Pvt Ltd, does not assume any responsibility or admits any liability whatsoever for the number of uses or re-uses or repetitions or damages to the sheets or concrete surface quality for reasons not attributable to manufacturing defects or for several other factors affecting the performance of the product. In the event of any occasional delamination in excess of the AQL (Acceptance Quality Level) of 3% established by the trade practices and also so declared by the seller hereby, the replacement of delaminated sheets or the surface area so observed shall me made expeditiously by the Seller or refund of value thereof as soon as possible without any further or other consequential or other losses.

|

|

|

Related Documents

Related knowledge documents :

![]() EPA-EPA-950-F-17-001

EPA-EPA-950-F-17-001

©Eximcorp India Pvt. Ltd., 88/14-17 Mundka Industrial Area, Road No. 12, Delhi Rohtak Road, New Delhi 110 041 Phone: +91 11 4061 0065, Fax: +91 11 4106 3444, Mobile: +91 98910 38202 | E-mail [email protected] |